- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Food Grade Carton

Zemeijia invests substantial resources in innovation and research and development, holding numerous patents for novel Food Grade Cartonand freshness-preserving paper boxes. These patented technologies have significantly expanded the application boundaries of our products. Meanwhile, Zemeijia assigns a one-on-one customer service specialist to each client, following the project progress throughout and ensuring smooth and timely communication.

Send Inquiry

Food grade carton is a type of packaging specifically designed for food products. Food grade carton is made from high-quality, food-safe materials that comply with strict hygiene and safety standards. Food grade cartons are sturdy and durable, providing excellent protection for the food items they contain.

Send And Inquiry

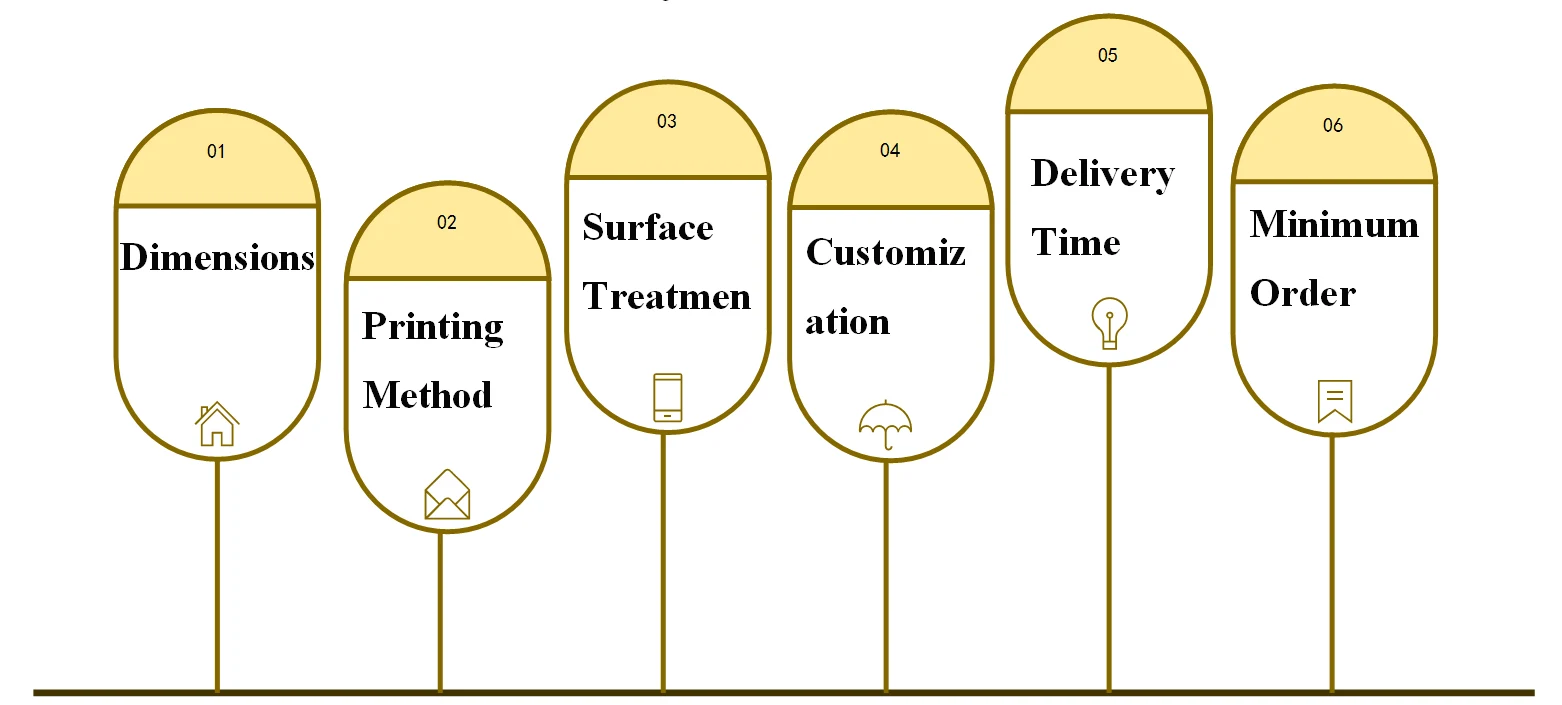

Which custom features can buyers choose from?

Send And Inquiry

What are the advantages of food grade carton?

● Food Safety Assurance: Food grade carton is made of materials that comply with food safety standards, being non-toxic and harmless, and will not contaminate the food. During storage and transportation, it effectively protects food from external contamination, ensuring the safety and hygiene of the food.

● Strong Durability: Food grade carton typically has high strength and toughness, capable of bearing certain weights and pressures without easy breakage. This makes it well-suited to protect food during transportation, reducing food waste and losses due to damage.

● Excellent Printability: The surface of food grade carton is smooth and easy to print on. Manufacturers can print relevant product information, such as brand logos, production dates, shelf lives, etc., on the carton, facilitating consumer understanding of the product and enhancing its brand value and market competitiveness.

● Eco-friendly and Recyclable: Food grade carton is usually made of recyclable eco-friendly materials, such as recycled pulp. After use, these cartons can be recycled and reused, helping to reduce resource waste and environmental pollution.

● Cost-effective: Compared to other food packaging materials, food grade carton has a lower cost. At the same time, due to its durability and printability, the carton can be used multiple times or for packaging a variety of products, further reducing costs.

Send And Inquiry

What is the process of making food grade carton?

|

Manufacturing Step |

Description |

|

Design and Conceptualization |

Collaborate with clients to develop custom designs based on product needs and brand requirements. From simple designs to complex folding patterns, ensure the carton perfectly showcases the product. |

|

Material Selection |

Use food-grade materials to ensure the packaging meets hygiene and safety standards. Select high-quality paperboard materials that are both durable and recyclable. |

|

Die-Cutting and Scoring |

Utilize advanced equipment for die-cutting and scoring, precisely cutting the paperboard into the desired carton shape, ensuring accuracy and consistency in the production process. |

|

Folding and Gluing |

Fold the carton along pre-scored lines and use automated gluing systems to seal the edges, ensuring the structural integrity of the carton. |

|

Printing and Surface Treatment |

Offer full-color printing, supporting various color systems such as CMYK and Pantone. Options for surface treatments like lamination, UV coating, and hot stamping are available. |

|

Quality Control and Finishing |

Conduct rigorous quality control checks to ensure each carton meets client specifications and industry standards. Provide various finishing options, such as embossing, debossing, and metallic coatings, to enhance the carton's visual appeal and functionality. |

Send And Inquiry

Application

Send And Inquiry

FAQ

Q: Are these cartons environmentally friendly?

A: Yes, three-layer postal corrugated boxes are usually made of recyclable materials, which meet environmental protection requirements.

Q: Is the carton sturdy and durable?

A: The carton is designed to be sturdy to ensure that it will not be damaged during transportation and storage.

Q: What if it’s damaged?

A: Contact us for a solution.

Q: How do I place an order?

A: Order online or contact sales.

Q: Can the carton be customized?

A: Yes, we can provide customized service, including printing or special design.