- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

Colour box gluing process challenges and solutions

2025-01-20

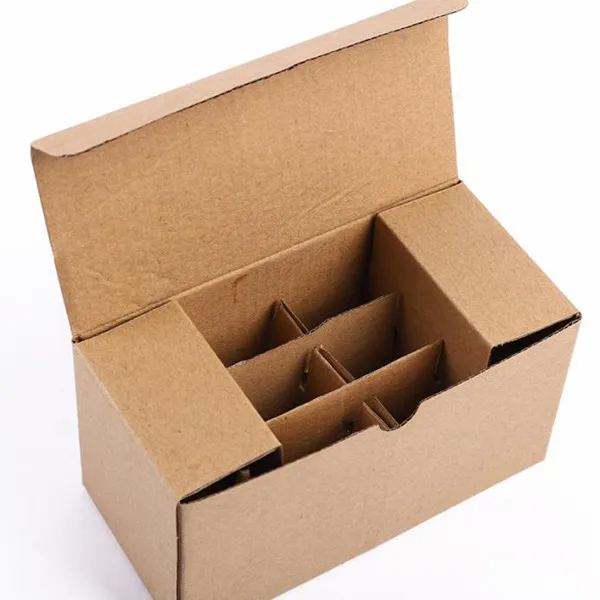

In the packaging and printing industry, the colour box gluing process is the key link to ensure the beautiful appearance and stable structure of the product. However, in the actual production process, this link also faces many challenges.

Improper selection of adhesive, how to solve the problem of poor adhesion?

Poor pasting is a common problem in the colour box gluing process, which is mainly caused by improper adhesive selection or carton surface treatment affecting the bonding effect. To solve this problem, it is necessary to choose an adhesive that is suitable for the carton material and ensure that the ambient temperature of the operation workshop is suitable.

How to ensure the moulding quality of the carton is deformed?

Carton deformation is usually caused by low die-cut plate accuracy, low adhesive concentration, or improper adjustment of the folder-gluer. In order to ensure the moulding quality of the cartons, the stability of the die-cutting quality should be ensured, the appropriate adhesive should be selected, and the folder-gluer should be adjusted. In addition, for cartons that have undergone surface treatment such as laminating and varnishing, the adhesive part should be properly treated before gluing to facilitate the penetration of adhesives.

Through the rational selection of adhesives, optimisation of the production environment, strengthening equipment adjustment and other measures, Zemeijia has been able to effectively solve various problems encountered in the process of colour box gluing.